Before entering the gowning room, step on a tacky mat and cover shoes.

FPA

JSS component is missing React implementation. See the developer console for more information.

By Cassie Mann

Every day, microelectronics employees don the bunny suit before they enter the cleanroom. While it may seem like a lot of work to cover yourself from head-to-toe, gowning procedures are one of the many ways we protect the product in a cleanroom.

At Northrop Grumman, many of our cleanrooms are classified as “Class 100,” meaning fewer than 100 particles, measuring 0.5 micron, per cubic foot of air. A human hair is 100 microns, so in order to protect the product, we need to clean 100 times smaller than that piece of hair. These are the same stringent standards used across the semiconductor manufacturing industry.

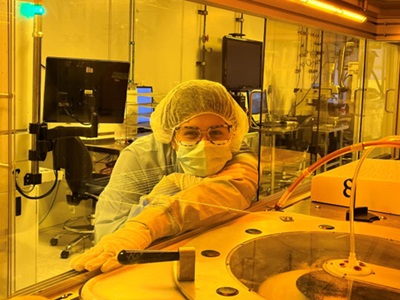

Cleanrooms maintain strong environmental controls to yield microelectronics, including keeping the area clean and debris-free through a variety of measures, such as air filtration, equipment cleaning, pressurization, and controlled entries and exits, as well as temperature and humidity control to keep the processing equipment stable. You may also notice yellow or amber lighting used to protect sensitive photoresist materials from unintended exposure to light and ensure the accuracy of the micro-patterns being created— a key requirement in both microelectronics and semiconductor device fabrication.

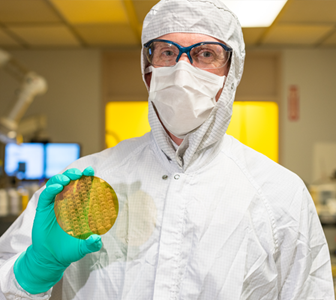

Justin Parke has been with Northrop Grumman for 17 years. While his career began as a high school physics teacher, Justin’s interest in emerging technologies led him to a role with the Northrop Grumman Microelectronics Center’s Process Integration group – the group responsible for putting together the process flows for fabricating (or, creating) wafers.

Stepping Into the Cleanroom

“People in the cleanroom are gowned head to foot, with almost no exposed skin – they have hoods, glasses, face masks – all to prevent particles, generated by humans, from impacting the product,” Justin shares. He knows the cleanroom gowning process well, as he suited up every day for his first 10 years at the Advanced Technology Lab (ATL), sometimes doing it four-to-five times a day.

Take a look at the steps microelectronics employees take as they prepare for the cleanroom space:

- Before entering the gowning room, you step on a tacky mat, which will remove dust and dirt from your shoes.

- Put on shoe covers, then enter the gowning room.

- Put your gloves on first, before you touch anything else, to prevent particulate exposure from your hands.

- Now, you’ll dress from the top down, starting with a bouffant to keep your hair in, a face mask, and a hood to cover your head.

- Next, you’ll put on the infamous bunny suit – the Tyvek jumpsuit that covers your entire body.

- Put booties over your feet.

- Put on glasses to protect your eyes.

- Add another pair of gloves, and now you’re ready to go!

“The gowning process definitely takes some getting used to. It can be claustrophobic – and hot – at first. But once you’re used to it, you don’t notice it quite as much,” Justin shared.

Behind the Cleanroom Scenes

Once in the cleanroom, this is where all microelectronic fabrication happens. Processes like photolithography, deposition, and etching are done to create integrated circuits on wafers, as well as assembly, packaging, quality control, and testing— all essential steps in producing reliable microelectronic and semiconductor devices.

Everyone in the cleanroom knows the importance of gowning and that there’s no room for error. There are temptations—like moving your face mask under your nose or not wearing your safety glasses —but microelectronic devices are extremely sensitive to contaminants such as dust, airborne microbes, and chemical vapors. A simple sneeze causes havoc. Even a single particle can cause defects, leading to failures or reduced performance.

To combat fatigue, employees will take frequent breaks to complete tasks outside the cleanroom or step into the gowning room to swap out equipment like face masks and gloves.

“Some of my best days passed the most quickly in the clean room because I was doing such interesting work,” Justin shares. “While cleanroom gowning may seem intimidating at first, I encourage anyone who is interested in this field to go for it. The opportunity to work on new and upcoming technologies is exciting and will keep you coming back.”

Life at Northrop Grumman

Your work at Northrop Grumman makes a difference. Whether you want to design next-generation aircraft, harness digital technologies or build spacecraft that will return humanity to the moon, you’ll contribute to technology that’s transforming the world. Check out our career opportunities to see how you can help define possible.